The Top 10 fiberglass mold market 2024 is shaping up to be an exciting arena filled with innovation, growth, and opportunity. As industries increasingly turn towards advanced materials for their durability, versatility, and cost-effectiveness, understanding the dynamics of this market becomes essential. In this comprehensive exploration, we will delve into the key trends affecting the fiberglass mold sector, uncover insightful data on market projections, and examine growth opportunities that lie ahead.

Global Fiberglass Trends Mold Market

The fiberglass mold market represents a significant segment of the composite materials industry, encompassing a wide range of applications across various sectors. This market has been experiencing robust growth driven by increased demand from end-user industries, advancements in production technology, and the growing popularity of lightweight materials.

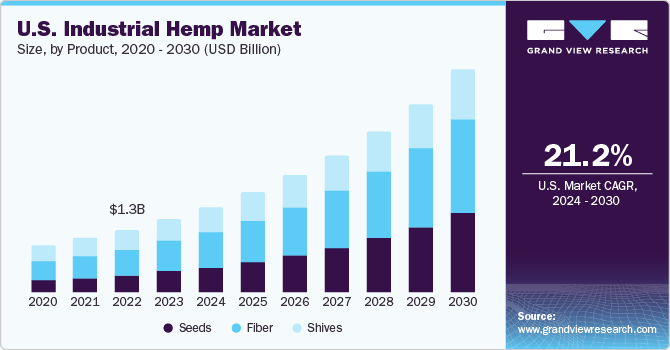

Fiberglass mold insights : Overview of Market Size and Growth

In recent years, the global fiberglass mold market has demonstrated resilience amidst economic fluctuations, with sustained investment propelling its expansion. A multitude of factors including technological innovations, heightened consumer demand for custom designs, and an increasing emphasis on sustainability are driving growth. The sector anticipated further growth as manufacturers adapt to evolving market trends and consumer preferences.

As we look toward 2024, projections indicate a favorable outlook for the fiberglass mold market. With ongoing developments in sectors such as automotive and aerospace, which heavily utilize fiberglass for its lightweight properties, there is potential for substantial revenue generation. Manufacturers are expected to enhance their production capabilities to meet rising demands while also focusing on efficiency and sustainability.

Trends Influencing the Market

Several key trends are influencing the fiberglass mold market as we head into 2024. These include:

- Innovation in Manufacturing Techniques: New methods such as automated processes, 3D printing, and advanced tooling techniques are revolutionizing mold production, enhancing quality and reducing lead times.

- Sustainability Focus: With growing environmental awareness, many companies are shifting towards sustainable practices, exploring bio-based resins and recyclable materials in the production of fiberglass molds.

- Customization Demand: As industries strive to differentiate their products, the demand for customized fiberglass molds is surging. Consumers are gravitating towards personalized solutions that cater to specific needs and aesthetic preferences.

These trends not only reflect the current climate of the industry but also signal areas ripe for future growth.

Key Manufacturers in the Fiberglass Mold Market

Understanding the competitive landscape is crucial for navigating the fiberglass trends in the market. Several manufacturers have established themselves as leaders, demonstrating innovation and adaptability in the face of changing market dynamics.

Major Players and Their Market Share

The market is characterized by a mix of large multinational corporations and smaller specialized firms. Some of the key players include established names like:

- Molded Fiber Glass Companies: Known for their extensive portfolio of fiberglass products, they have a strong foothold in various applications including marine and automotive sectors.

- KUKA AG: This organization is noted for its automation solutions, streamlining manufacturing processes to enhance efficiency within the fiberglass mold sector.

- Nikon Metrology: Renowned for precision measurement solutions, Nikon's involvement in mold production emphasizes quality assurance and product consistency.

Each of these companies brings unique strengths and market approaches that contribute to the overall dynamics of the fiberglass mold market.

Market Share Analysis

The competitive positioning of these manufacturers plays a critical role in dictating market trends. By analyzing market share and performance metrics, one can glean insights into strategic movements within the industry. Factors such as innovation cycles, merger and acquisition activity, and geographic reach all inform how these players carve out their respective niches in the market.

An ongoing trend among key players is the investment in research and development aimed at improving production technologies and exploring new applications for fiberglass molds. Such initiatives can confer competitive advantages, allowing manufacturers to respond swiftly to changes in consumer demand and technological advancements.

Application Segments Driving Growth

The diverse applications of fiberglass molds underscore their versatility and utility across various sectors, propelling market growth. From automotive to aerospace, construction, and beyond, fiberglass molds are ingrained in processes that require precision and durability.

Automotive Sector

The automotive industry stands as a primary driver of fiberglass mold growth. The shift towards lightweight materials for enhanced fuel efficiency presents ample opportunities for fiberglass utilization.

Fiberglass composites are increasingly replacing traditional materials due to their strength-to-weight ratio, leading to reduced vehicle weight without compromising safety or performance.

Additionally, the rise of electric vehicles (EVs) has prompted manufacturers to explore innovative design solutions using fiberglass, creating molds that cater to unique components of EV systems.

Aerospace Industry

In the aerospace sector, fiberglass molds play an integral role in the manufacturing of aircraft components. The ability to create complex shapes and designs with fiberglass provides manufacturers with the flexibility necessary to optimize aerodynamics and reduce weight.

As airlines prioritize fuel efficiency to lower operational costs, the demand for lightweight composite materials—including fiberglass—continues to surge. This trend is likely to persist as the industry seeks to balance performance with environmental considerations.

Construction Applications

The construction industry is another prominent area where fiberglass molds are making significant inroads. From structural components to decorative elements, fiberglass offers unparalleled design flexibility, making it a favored choice among architects and builders.

The use of fiberglass in construction extends to infrastructure projects as well. Its resistance to corrosion and weathering makes fiberglass molds ideal for producing durable components that withstand the rigors of outdoor environments.

Geographical Trends in Fiberglass Mold Use

The global distribution of fiberglass mold demand reveals regional trends that are vital for stakeholders in the industry. Understanding geographic nuances can help businesses make informed decisions about market entry strategies and resource allocation.

North America Market Dynamics

North America remains a leading region for fiberglass mold usage, particularly driven by its automotive and aerospace sectors. U.S.-based manufacturers are at the forefront of technological advances in mold production, reinforcing the region's position as a hub for fiberglass innovation.

Furthermore, government investments in infrastructure and transportation projects continue to bolster demand for fiberglass molds, as materials that offer durability and low maintenance become increasingly sought after.

Asia-Pacific Growth Potential

The Asia-Pacific region represents a burgeoning market for fiberglass molds due to rapid industrialization and urbanization. Countries like China and India are experiencing exponential growth in their automotive and construction industries, driving the need for advanced manufacturing materials.

Emerging economies in this region are also witnessing an uptick in demand for consumer goods made from fiberglass, as disposable income rises and consumers seek high-quality, durable products.

European Market Characteristics

Europe exhibits a mixed landscape of fiberglass mold applications, with strong emphasis on sustainability and regulatory compliance. European manufacturers are investing in eco-friendly production practices, reflecting consumer preferences directed towards greener alternatives.

Additionally, the region's stringent regulations regarding emissions and material safety continue to shape production standards, providing opportunities for innovation in mold design and manufacturing processes.

Technological Advancements in Mold Production

Technological advancements significantly influence the evolution of the fiberglass mold market. By leveraging cutting-edge techniques and tools, manufacturers can enhance production efficiency and product quality.

Automation and Robotics

The integration of automation and robotics in mold production is transforming how fiberglass molds are manufactured. Automated systems enable precise control over production processes, minimizing errors and maximizing consistency.

Robotics also facilitate the handling of complex fiberglass materials, leading to improved safety and workflow efficiencies. As manufacturers seek ways to streamline operations while maintaining high standards, automation will undoubtedly play a central role.

3D Printing Innovations

3D printing technology is revolutionizing mold-making processes, allowing for rapid prototyping and customization. This innovation enables manufacturers to create intricate designs that were previously difficult or costly to achieve using traditional methods.

Moreover, 3D printing reduces waste associated with traditional mold production, aligning with sustainability goals in the fiberglass industry. As this technology continues to mature, the potential for disruptive change in mold production practices grows.

Advanced Material Research

Research into advanced materials is paving the way for new formulations that enhance the performance characteristics of fiberglass molds. Innovations such as hybrid composites and reinforced resins improve the mechanical properties of fiberglass, expanding its applicability in demanding environments.

By investing in RD, manufacturers can develop smarter materials that meet the evolving needs of various industries, ensuring they remain competitive in a rapidly changing market.

Regulatory Environment Impacting the Market

The regulatory landscape surrounding fiberglass mold manufacturing plays a crucial role in shaping market dynamics. Compliance with regulations ensures product safety and environmental responsibility.

Safety Standards and Regulations

Safety standards governing the use of fiberglass materials focus on protecting workers and end-users. Organizations such as OSHA in the United States outline guidelines to mitigate hazards associated with fiberglass exposure, prompting manufacturers to adopt safety protocols during production.

These regulations not only safeguard employees but also enhance the credibility of manufacturers committed to ethical practices, fostering consumer trust in fiberglass products.

Environmental Considerations

Environmental regulations are increasingly influencing the fiberglass mold market. As governments worldwide intensify efforts to address climate change, there is pressure on manufacturers to adopt sustainable practices.

Legislation encouraging the use of recyclable materials and limiting harmful emissions necessitates investment in cleaner technologies. Companies that proactively embrace these environmental considerations position themselves favorably in the eyes of consumers and regulators alike.

International Trade Regulations

Trade policies impact the fiberglass mold market, especially as globalization facilitates cross-border supply chains. Tariffs and import/export regulations can affect the cost structure for manufacturers, influencing pricing strategies and market access.

Navigating these regulatory complexities requires strategic insight, as companies must remain vigilant in adapting to shifts in trade agreements impacting their operations and profitability.

Market Challenges and Opportunities

While the fiberglass mold market presents numerous opportunities for growth, it is not without its challenges. Identifying these barriers enables stakeholders to devise effective strategies for navigating a competitive landscape.

Economic Fluctuations

Economic uncertainty poses a challenge for the fiberglass mold market, as fluctuations in demand can adversely impact production volumes. Global events, such as pandemics or geopolitical tensions, can disrupt supply chains, leading to increased costs and delays.

To mitigate these risks, manufacturers are encouraged to diversify their product offerings and markets, ensuring they remain agile in responding to changing economic conditions.

Competition from Alternative Materials

As industries continually seek cost-effective solutions, competition from alternative materials threatens the fiberglass mold market. For instance, advancements in metal and polymer composites provide viable options that could displace fiberglass in certain applications.

Manufacturers must emphasize the unique benefits of fiberglass, such as its lightweight properties and durability, to maintain market relevance and foster consumer loyalty.

Opportunities in Emerging Markets

Despite challenges, emerging markets present abundant opportunities for growth. As developing nations invest in infrastructure and industrial projects, the demand for fiberglass molds is poised to increase.

Astute manufacturers should focus on establishing partnerships and local production facilities in these regions to capitalize on burgeoning opportunities while minimizing logistical hurdles.

Consumer Preferences Influencing Market Dynamics

Consumer preferences have a profound impact on the fiberglass mold market, shaping product offerings and dictating market strategies. Understanding these preferences is essential for manufacturers seeking to align with evolving consumer needs.

Design and Aesthetic Trends

Today's consumers place a premium on aesthetics and design flexibility. Fiberglass molds allow for intricate shapes and vibrant finishes that appeal to modern sensibilities.

As industries push for visually striking products, manufacturers must innovate in mold design, ensuring they offer customized options that resonate with consumers.

Performance and Durability Expectations

Consumers increasingly expect superior performance and longevity from products, including those made using fiberglass molds. The pursuit of higher quality materials drives manufacturers to invest in robust testing and validation processes.

By emphasizing fiberglass's advantages in terms of strength, resilience, and resistance to environmental factors, manufacturers can better address consumer concerns and build brand loyalty.

Sustainability Consciousness

With growing awareness of environmental issues, consumers are gravitating towards brands that demonstrate commitment to sustainability. Manufacturers embracing eco-friendly practices such as using recyclable materials and adopting green production methodologies stand to benefit from this shift in consumer attitude.

To effectively communicate their sustainability efforts, manufacturers must engage in transparent marketing campaigns that highlight their responsible business practices, thereby resonating with environmentally-conscious consumers.

Sustainability Initiatives within the Industry

The fiberglass mold industry is increasingly recognizing its responsibility to pursue sustainable practices and minimize its environmental impact. Efforts towards sustainability are multifaceted and aimed at reshaping perceptions about fiberglass manufacturing.

Eco-Friendly Material Development

Innovations in eco-friendly materials are gaining traction within the fiberglass mold market. Manufacturers are exploring bio-based resins and recyclable composites, thus reducing reliance on conventional materials that contribute to environmental degradation.

This shift not only improves the environmental footprint of fiberglass products but also caters to the growing consumer demand for sustainable options.

Waste Reduction Strategies

Minimizing waste is a key component of sustainability initiatives. Many manufacturers are adopting lean production principles to optimize resource use and limit material waste during the mold-making process.

Implementing practices such as recycling scrap materials and improving inventory management contributes to a more sustainable production model, aligning with broader industry trends towards circular economy principles.

Partnerships for Sustainability

Collaboration between industry stakeholders is essential for advancing sustainability goals. Manufacturers are forging partnerships with suppliers, researchers, and regulatory bodies to drive innovation in sustainable practices.

By working collectively towards shared sustainability objectives, stakeholders can amplify their impact, ultimately contributing to a more responsible and environmentally-conscious fiberglass mold industry.

Future Market Projections and Forecasts

As we look toward the future, the fiberglass mold market is positioned for continued growth and transformation. Various factors will shape its trajectory, guiding manufacturers' strategic decisions.

Growth Rates and Market Evolution

Market forecasts indicate that the fiberglass mold sector will witness steady growth through 2024 and beyond, fueled by expanding applications across multiple industries. As technological advancements continue to redefine production practices and material formulations, manufacturers who adapt swiftly will capture a larger share of the market.

Emerging trends such as the rise of electric vehicles and increased focus on sustainability are expected to further catalyze growth, presenting opportunities for innovation and diversification.

Evolving Consumer Demands

Consumer preferences are continuously evolving, requiring manufacturers to stay attuned to market trends. Those who prioritize research and development will be better positioned to meet changing demands, offering products that resonate with contemporary values.

Furthermore, as digital transformation permeates industries, the integration of smart technologies into fiberglass mold production could set the stage for new growth avenues, enhancing operational efficiency and product customization.

Adapting to Regulatory Changes

Regulatory landscapes are prone to change, and manufacturers must remain vigilant in monitoring shifts in compliance requirements. Embracing proactive approaches to regulation can yield long-term benefits, ensuring that products meet safety and environmental standards while aligning with consumer expectations.

Conclusion

The Top 10 fiberglass mold market 2024 is characterized by a dynamic interplay of growth drivers, technological advancements, and evolving consumer preferences. As industries increasingly embrace fiberglass for its versatility, durability, and sustainability, the market is poised for robust expansion.

Stakeholders must navigate challenges such as economic fluctuations and competition from alternative materials while capitalizing on emerging opportunities in developing markets and consumer-driven trends. By prioritizing innovation, sustainability, and responsiveness to regulatory changes, manufacturers can position themselves strategically in this competitive landscape.

In summary, the future of the fiberglass mold market is bright, with myriad opportunities awaiting manufacturers ready to adapt and evolve with the changing tides of industry demands and consumer expectations.

More detail : fiberglass mold market